Contact Info

- Keji 1st Road, Panwan Industrial Park, Jiayu County, Wuhan Xingang Industrial New Town

- Office Building, No.07, Creative World, Yezhihu West Road, Wuhan

- +86 (027) 8877 9150

- +86 133 9716 9509

- +86 (027) 8877 9150

- service@whhdpk.cn

Installation method of O-

O-ring installation recommendations are as follows:

• O-rings should avoid contact with sharp edges of mounted parts, must be chamfered or deburred

• No dirt or other residue in the trench or on the O-ring

• Avoid confusion with other O-rings (refer to color markers)

• Do not use glue on O-rings (it will cause hardening)

• O-rings should be installed to avoid distortion

• Before using detergent/detergent, it must be verified that the O-ring is resistant

• Do not use hard tools with sharp surfaces

• For installation purposes, the O-ring inner diameter can be briefly expanded to a maximum of 20%

O-ring installation Angle Suggestion:

• In order to avoid damage to the O-ring during installation, we must consider the mounting Angle of the drilling hole and shaft during the design stage.

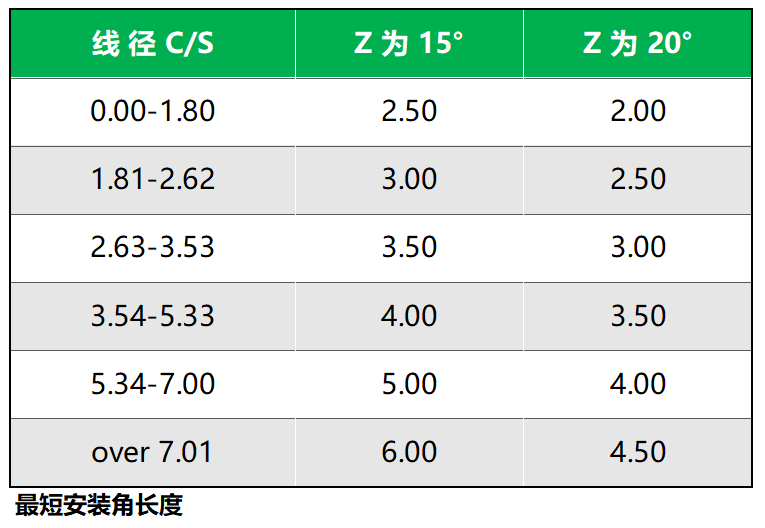

The following table lists the minimum mounting Angle lengths allowed for piston and piston rod seals under different wire diameter conditions.

Next:Null