Contact Info

- Keji 1st Road, Panwan Industrial Park, Jiayu County, Wuhan Xingang Industrial New Town

- Office Building, No.07, Creative World, Yezhihu West Road, Wuhan

- +86 (027) 8877 9150

- +86 133 9716 9509

- +86 (027) 8877 9150

- service@whhdpk.cn

Industry news

Seals are to solve the problem of mechanical equipment leakage, so why will mechanical equipment leak?

①Machining clearance

The surface of the machined mechanical products must have various defects and shape and size deviations, so there will inevitably be gaps at the joints of the mechanical parts. Gaps are bound to create leaks.

②A method of reducing or eliminating gaps

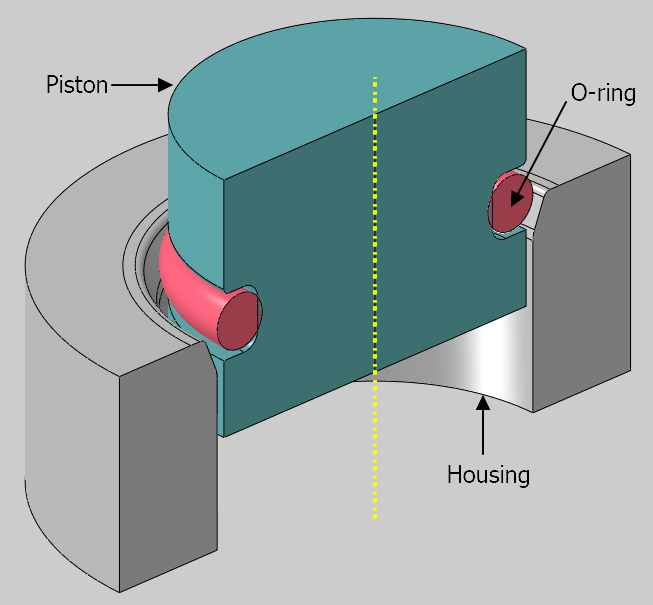

Reducing or eliminating the gap is the main way to stop the leak is to install the appropriate seals. The role of sealing is to seal the gap between the joint surface, isolate or cut off the leakage channel, increase the resistance in the leakage channel, or add a small work element in the channel to cause pressure on the leak, and partially offset or completely balance the pressure difference causing the leak to prevent the leak.

③Additional factors that should be considered in vacuum systems: leakage and diffusion

Leakage: that is, under the action of pressure difference, the leak of the sealed medium through the capillary tube of the sealing material is called leakage;

Diffusion: that is, under the action of concentration difference, the sealed medium is transferred through the material produced by the sealing gap or the capillary tube of the sealing material to become diffusion.

We specializes in the production of high quality seals, our main products are O-ring, Square Rings, X-Rings, Y-rings, U-rings, High precision miniature seals, Bonded Seals, ED seals, hydraulic seals, dust rings, Custom products, shaped rubber gaskets, oil seals, rotating grey ring, rotating St seal, spring energized seal and so on.