Contact Info

- Keji 1st Road, Panwan Industrial Park, Jiayu County, Wuhan Xingang Industrial New Town

- Office Building, No.07, Creative World, Yezhihu West Road, Wuhan

- +86 (027) 8877 9150

- +86 133 9716 9509

- +86 (027) 8877 9150

- service@whhdpk.cn

Industry news

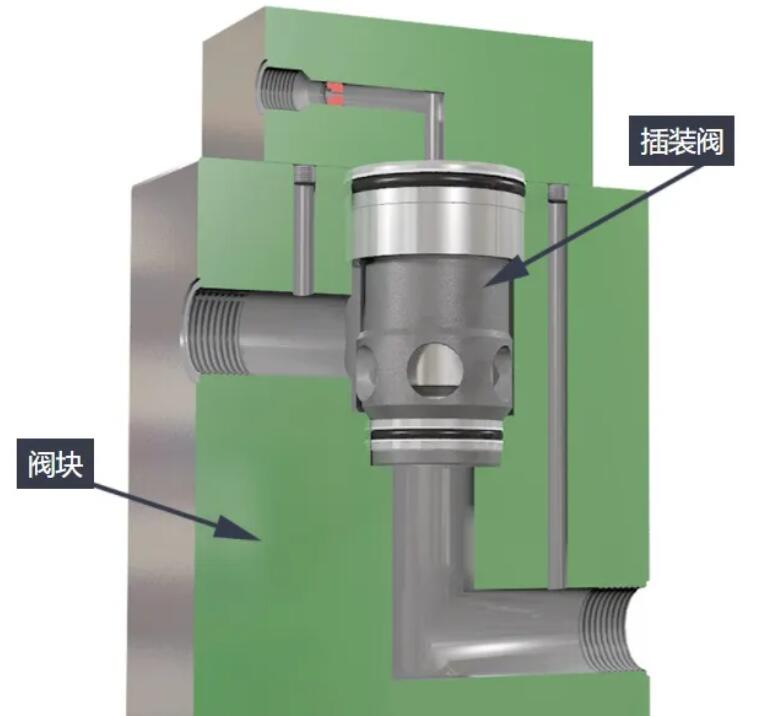

① Introduction of cartridge valve

Cartridge valves usually need to be installed in the hydraulic integrated block to work normally, and their types also include pressure control valves, direction control valves and flow control valves. The hydraulic block is generally made of steel or aluminum, and then needs to be machined into the block to facilitate the insertion of the cartridge valve. The hydraulic block was chosen because its high degree of integration saves space and reduces the number of accessories such as hoses and joints. The number of hoses, fittings and other accessories is reduced, so the leakage point is greatly reduced. Even with post-maintenance, it's easier to deal with an integrated valve block than a bunch of intricate pipes.

② The application of O-ring of cartridge valve

O-rings are rich in materials, and the commonly used materials in cartridge valves are nitrile rubber O-rings and fluoro rubber O-rings. However, it is not compatible with phosphate ester hydraulic fluids.

We selected EPDM O-seals that are compatible with the following product grades of type 4 or 5 hydraulic fluids: Skydrol®, Fyrquel®, HyJet™ and Pyrogard™ 53 and are stable over a wide temperature range. Cartridge valves with EPDM seals (EPDM seals) are suitable for phosphate working media. Exposure to petroleum-based hydraulic fluids or lubricating oils will cause damage to EPDM seals. It is not recommended to expose EPDM seals to aromatic hydrocarbons, such as in the food industry.

We specializes in the production of high quality seals, our main products are O-ring, Square Rings, X-Rings, Y-rings, U-rings, High precision miniature seals, Bonded Seals, ED seals, hydraulic seals, dust rings, Custom products, shaped rubber gaskets, oil seals, rotating grey ring, rotating St seal, spring energized seal and so on.